API 581, the Risk-Based Inspection (RBI) methodology, provides valuable advantages to the oil and gas sector. Through the adoption of this industry standard, companies can greatly improve their management practices concerning equipment integrity.

The key benefit of API 581 lies in its capacity to prioritize inspection activities based on risk levels, enabling organizations to allocate their resources in a highly effective manner. Read on to know about the fundamentals of API 581, the formula of PoF and CoF for RBI determination, the inspection planning, and the benefit of the API 581 application.

What Is API 581?

API 581 is a recommended practice that provides a quantitative Risk-Based Inspection (RBI) procedure for stationary equipment such as pressure vessels, pipelines, storage tanks, and heat exchanger tube bundles. This document is broken into three sections: RBI methodology, Probability of Failure (PoF), and Consequences of Failure.

API RP 581, created and published by the American Petroleum Institute (API), provides advanced risk-based inspection methodologies that expand on the minimal criteria given in API RP 580.

API 581, established in 2000, builds on API 580 by providing particular mathematical methods for creating thorough inspection plans. The document is broken into three sections: RBI methodology, PoF, and CoF.

API 581 has undergone multiple modifications to keep up with industry changes, with the most recent version issued in April 2016. Modern risk management takes into account a wide range of elements, in addition to on-site safety considerations. Today, API 581 takes into account:

- Employees face risks on-site

- Off-site risks for the surrounding community

- Business disruption risks

- Environmental harm hazards

API 581 also specifies a methodology for prioritizing inspections based on the risk level of process equipment. By evaluating both the Probability of Failure (PoF) and the Consequence of Failure (CoF), API 581 assists businesses in focusing their resources on equipment that offers the highest risks, hence lowering overall plant risk.

What is RBI in Oil and Gas?

Risk-depending Inspection (RBI) is a strategy for monitoring asset integrity that prioritizes inspections depending on the risk level assigned to each asset.

Companies can use RBI to maximize resources by prioritizing high-risk equipment above assets with low or minor hazards. This method improves overall operational efficiency and safety.

What Are The Major Objectives for RBI According To API 581?

Referring to API 581, RBI has four major goals:

- Assess and quantify risks for all relevant equipment.

- Enhance a comprehensive understanding of risks and their underlying factors.

- Facilitate efficient risk management practices.

- Mitigate risks associated with the operation of processing facilities.

The API 581 methodology is divided into five sections, each addressing different aspects of RBI and equipment integrity management.

Part 1: Introduction to Risk-Based Inspection Methodology in API 581

The first part of API 581 introduces and explains the Risk-Based Inspection (RBI) methodology. This part gives the underlying knowledge needed to grasp RBI ideas and concepts. It generally addresses the following topics:

- Scope and Objectives of API 581

- Introduction to RBI

- Risk Concepts

- RBI Process

- Relationship to Other Industry Practices:

- Compliance and Certification

Part 2: Probability of Failure Methodology in API 581

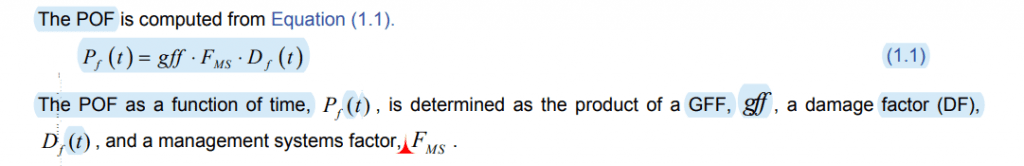

The Probability of Failure (PoF) is a method for assessing the likelihood of equipment failure over a certain time period. PoF is calculated by using historical data, expert opinions, and mathematical models to estimate the likelihood of failure for each identified damage mechanism in a specific piece of equipment.

The PoF result is usually expressed as a probability per unit of time, such as a year. For example, a PoF of 0.01 per year represents a 1% likelihood of equipment failure within a year.

Part 3: Consequence of Failure Methodology in API 581

The term “Consequence of Failure” (CoF) refers to the potential effects of equipment failure, such as environmental harm, safety concerns, production loss, or reputational damage. The effects are often evaluated on a scale of mild to catastrophic and may be monetary in nature.

CoF is calculated by weighing the severity of the effects against parameters such as equipment type, operating conditions, location, and importance to the production process.

CoF is an important component of RBI since it assesses the entire risk associated with a piece of equipment. Combining CoF with PoF allows an RBI program to identify high-risk equipment and prioritize inspection and maintenance tasks. This strategy allows operators to better manage dangers by focusing on equipment with the highest risk ratings.

Part 4: Inspection Planning Methodology in API 581

Inspection planning calculates the risk of equipment over time until it achieves a risk objective determined by the owner-user. Inspections should take place on or before the day when the risk target is met.

Inspections do not eliminate equipment’s inherent danger, but they do provide information on its damaged state and lessen ambiguity.

Thus, the likelihood of containment loss is related to the quality and quantity of information obtained from earlier inspections, as well as the inspection method’s ability to quantify damage.

To maintain an efficient and up-to-date inspection approach, risk-based inspection planning requires conducting regular reviews of equipment risks. This improves equipment reliability, reduces downtime, and promotes operational safety and efficiency.

Part 5: Special Equipment

The fifth section of API 581 covers the Risk-Based Inspection (RBI) method for evaluating specialized equipment under the API 581 standard. This section contains principles and specific variables to examine when assessing the risks associated with specialized equipment used in the petroleum, petrochemical, and natural gas industries.

The content of Part 5 typically includes:

- Scope and Objectives

- Introduction to Special Equipment

- Risk Assessment Considerations

- Data Gathering and Evaluation

- Risk Analysis and Prioritization

- Inspection Planning and Decision-Making

- Documentation and Reporting

What Is Risk Analysis in API 581 Risk-Based Inspection?

Risk analysis involves identifying, evaluating, and ranking potential dangers or vulnerabilities that a system or process may face. In specific fields like the petroleum industry, API establishes principles and regulations for risk-based inspection, including applying risk matrices to gauge risk severity.

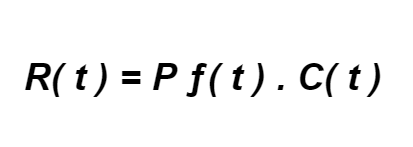

The calculation of risk can be determined as a function of time by combining the likelihood of failure and the impact of failure, as shown in API 581 document above.

API 581 offers instructions and approaches for performing risk analysis, which involves gathering data, evaluating equipment conditions, identifying potential failure modes and degradation mechanisms, quantifying risks, and setting criteria for acceptable risk levels. The standard highlights the significance of considering factors like operating conditions, environmental impacts, and the consequences of failure during the risk analysis procedure.

What Are The Benefits of Risk-Based Inspection based on API 581?

Applying the API 581 standard enables risk-based inspection (RBI) to be conducted on pressure equipment within the oil and gas sector can lead to various advantages, such as:

- Complying with the API 581 standard can improve safety by identifying potential equipment failures and prioritizing inspection activities.

- It can increase equipment reliability by addressing equipment issues before they become major problems.

- Cost savings can be achieved by optimizing inspection schedules and reducing unnecessary inspections.

- Compliance with API 581 can help meet regulatory requirements for the inspection and maintenance of pressure equipment.

- The standard provides a structured approach to risk-based inspection, allowing for informed decision-making about inspection priorities and maintenance activities.

- Communication and collaboration between different stakeholders in the inspection process are facilitated by the common language and methodology provided by the standard.

Based on the benefits mentioned, understanding API 581 and enrolling in API 580 and API 581 training course are important because they give individuals the knowledge and skills to effectively implement risk-based inspection (RBI) methodologies.

Even further, taking API 581 training can help professionals gain an understanding of the RBI process and the various steps involved, as well as learn how to interpret and apply the API 581 standard.

It can also provide insight into best practices for implementing RBI programs and improving safety and reliability in operations. PetroSync aims to help individuals enhance their professional skills and advance their career opportunities in the oil and gas industry. Reserve your API 581 training spot today.

Credit header image: Freepik

Results-oriented and thorough SEO specialist with extensive experience in conducting keyword research, developing and implementing digital website promotion strategies and plans, managing campaigns to develop company websites in the digital world, excellent knowledge of marketing techniques and principles, and attentive strong attention to detail.