As one of the popular M&R certifications, CMRP guides how to prepare for the exam by accessing its Body of Knowledge. Exploring BoK helps you understand the fundamental principles, best practices, and emerging trends in maintenance and reliability management. This article will delve into each pillar of the CMRP BoK, providing insights into the key concepts and areas you must cater to pass the CMRP exam successfully.

What Is CMRP Body of Knowledge?

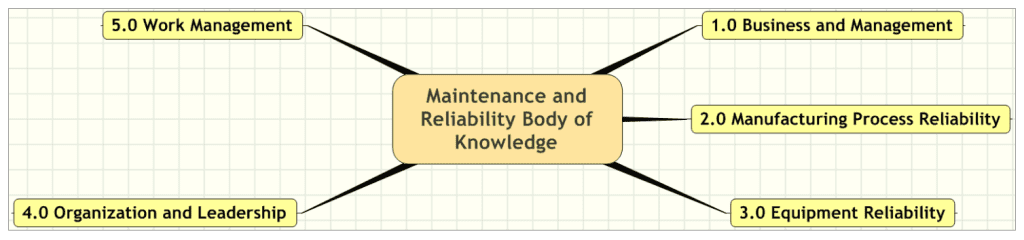

The CMRP Body of Knowledge (BoK) is a comprehensive compilation of essential topics, principles, and best practices that form the foundation for individuals pursuing the Certified Maintenance and Reliability Professional – CMRP certification.

Body of Knowledge encompasses various domains and knowledge areas related to maintenance, reliability, and physical asset management. The CMRP BoK serves as a roadmap, guiding you in developing the core competencies and skills necessary for effective maintenance and reliability practices.

Studying the CMRP BoK can enhance your expertise and broaden your maintenance and reliability management knowledge.

What Topics Are Covered Under The Business and Management Pillar in CMRP?

This topic focuses on the abilities required to align an organization’s business objectives with suitable maintenance and reliability objectives, enhancing and contributing to the organization’s overall business outcomes.

1.1 Create Strategic direction and plan for M&R operations

- Provide vision and direction

- Provide clear and measurable goals

1.2 Administer Strategic plan

- Develop support

- Obtain approval and resources

- Implement plans

1.3 Measure Performance

- Select key performance indicators

- Track and report

1.4 Manage organizational plan

- Develop a change management process

- Communicate benefits

1.5 Communicate with stakeholders

- Provide management reports

- Inform staff

- Coordinate with operations

1.6 Manage environmental-health-safety risk

- Support community EHS goals

- Support security goals

- Conform to applicable regulations

- Provide EHS training

What Topics Are Covered Under The Manufacturing Process Reliability Pillar in CMRP?

This topic establishes a connection between maintenance and reliability activities and the organization’s manufacturing process, ensuring that these activities enhance and optimize the manufacturing process.

2.1 Understand the applicable processes

- Document process flow

- Understand process parameters

- Understand quality specifications

2.2 Apply process improvement techniques

- Identify production losses

- Establish a continuous improvement process

2.3 Manage the effects of the change to processes and equipment

- Establish change protocol

- Update documentation

- Update procedures

2.4 Maintain processes following applicable standards and regulations

- Understand industry standards

- Understand regulatory requirements

- Ensure compliance

What Topics Are Covered Under The Equipment Reliability in CMRP?

This topic covers two types of activities that pertain to the equipment and processes under the responsibility of maintenance and reliability professionals. The first set of activities involves evaluating the equipment and processes’ reliability, availability, maintainability, and criticality.

The second set of activities involves selecting and implementing the most suitable maintenance practices to ensure that the equipment and processes consistently perform as intended while prioritizing safety and cost-effectiveness.

3.1 Determine equipment reliability expectations

- Identify reliability goals

- Identify process expectations

3.2 Evaluate equipment reliability and identify improvement opportunities

- Measure and track performance

- Determine best-demonstrated performance

- Analyze gaps

3.3 Establish a strategic plan to ensure reliability of existing equipment

- Identify appropriate analysis techniques

- Develop maintenance strategy and tactics

3.4 Establish a strategic plan to ensure reliability of new equipment

- Establish reliability specifications

- Establish acceptance criteria

- Obtain complete documentation

3.5 Cost-justify selected plans for implementation

- Conduct cost-benefit analysis

- Communicate benefits

- Obtain approval

3.6 Implement selected plans to ensure equipment reliability

- Apply reliability strategies

- Establish organization structure

- Provide resources

3.7 Review the reliability of equipment and adjust the reliability strategy

- Assess key performance indicators

- Analysis deviations

- Identify relevant best practices

- Implement continuous improvement

What Topics Are Covered Under The Leadership and Management Pillar in CMRP?

This topic encompasses the processes aimed at ensuring that the maintenance and reliability personnel are suitably qualified and assigned to accomplish the goals of the maintenance and reliability organization effectively.

4.1 Determine organizational requirements

- Review strategic plan

- Determine required skills

- Determine required staffing levels

4.2 Analyze organizational capability

- Inventory staff skills

- Determine performance gaps

4.3 Develop the organizational structure

- Establish reporting channels

- Determine roles

- Determine responsibilities

- Manage reorganization

4.4 Develop personnel

- Provide training

- Obtain needed expertise

- Delineate career paths

4.5 Lead and manage people

- Develop leadership skills

- Assess performance

- Promote a cooperative work environment

- Facilitate communication

What Topics Are Covered Under The Work Management Pillar in CMRP?

This subject area emphasizes the competencies required to execute maintenance and reliability tasks efficiently. It encompasses activities such as planning and scheduling, ensuring the quality of maintenance work, and managing stores and inventory.

5.1 Identify, validate, and approve work

- Establish work identification processes

- Select and approve viable work

5.2 Prioritize work

- Develop a formal prioritizing system

- Implement a formal prioritizing system

5.3 Plan work

- Develop job package

- Including scope and procedures

- Including materials and tools

- Including testing

5.4 Schedule work

- Develop scheduling process

- Produce work schedule

- Balance resources

- Monitor backlog

- Manage break-in work

- Coordinate equipment access

5.5 Execute work

- Manage labor

- Manage material and services

- Control Productivity

- Ensure EHS compliance

5.6 Document work

- Create post work document process

- Record failure events and failure modes

- 5.7 Analyze work and follow-up

- Compare actual work with a plan

- Identify variances

5.8 Measure work management performance

- Establish performance indicators

- Report schedule compliance and rework

5.9 Plan and execute projects

- Define scope

- Estimate project and life cycle costs

- Apply critical path methods

- Track progress

- Coordinate staffing

5.10 Use information technologies effectively

- Leverage capabilities of data historian

- Process control systems

- Condition monitoring software

- EAM, CMMS systems functionality

5.11 Manage resources and materials

- Control materials inventory

- Manage spares and equipment

- Establish the MRO procurement process

- Manage contractors

What Are The Benefit of Following Body of Knowledge as CMRP Preparation?

Embracing the CMRP Body of Knowledge (BoK) brings numerous advantages for maintenance and reliability professionals, as outlined below:

1. Comprehensive Understanding

The BoK ensures a thorough grasp of vital concepts, principles, and practices in maintenance and reliability management. By studying the BoK, you will gain profound knowledge and expertise in this field, enabling you to navigate and apply the fundamental elements that drive successful maintenance and reliability strategies.

2. Structured Learning

You can arrange a well-organized framework for studying and preparing for the CMRP exam enabling a systematic approach to learning.

3. Knowledge Enhancement

Engaging with the BoK can deepen your knowledge, strengthen your skills, and enhance your overall maintenance and reliability management competence.

4. Broad Coverage

The Body of Knowledge (BoK) covers various topics, providing a comprehensive understanding that applies to various industries and sectors. By exploring the BoK, you can thoroughly grasp essential principles, practices, and relevant and valuable methodologies in diverse professional contexts.

5. Versatile Problem-Solving

CMRP-certified professionals who rely on the BoK acquire the ability to address diverse challenges, make informed decisions, and contribute effectively to the success of your organizations.

6. Enhanced Credibility

Relying on the BoK adds credibility and recognition to the CMRP certification, validating individuals’ expertise and maintenance and reliability management capabilities.

PetroSync offers a comprehensive CMRP training course resembling the Body of Knowledge (BoK). Our training course provides extensive materials and resources, covering the essential topics outlined in the BoK.

By enrolling in PetroSync’s CMRP training, you can enhance your knowledge and skills in maintenance and reliability management, deeply understanding the principles, practices, and methodologies emphasized in the BoK.

The training equips you with the necessary tools and insights to excel in your roles, enabling you to apply industry-leading practices and contribute effectively to your organization’s maintenance and reliability objectives.

PetroSync’s CMRP training ensures that you are well-prepared to address the challenges and complexities of your field, empowering you to impact your organization’s overall performance and success positively.

Credit header image: Pexels

SEO specialist by day, fact-checker by night. An avid reader and content writer dedicated to delivering accurate and engaging articles through research and credible sources.