Understanding the impact of the Physics of Failure (P-o-F) on equipment reliability is crucial in today’s complex technological landscape. This article delves into the relationship between P-o-F and the reliability of equipment, examining how the systematic identification of potential failures and their root causes contributes to enhanced reliability.

What Is The Physics of Failure?

The Physics of Failure is a scientific approach used to understand how physical, chemical, mechanical, thermal, or electrical stresses can degrade or cause the failure of electrical, electronics, or electromechanical items such as:

- Individual Parts

- Sub-assemblies

- Modules, and

- Complete Equipment

The physics of failure methodology goes beyond simply addressing the visible symptoms of failure and seeks to uncover the root causes embedded in the physical processes at play.

By examining the interactions between materials, environmental conditions, and external stressors, the Physics of Failure allows for a proactive approach to identifying potential weaknesses before they escalate into critical issues. This understanding aids in the development of robust strategies for maintenance, design, and operational practices, contributing to the overall reliability and longevity of components and systems.

What Is The Importance of the Physics of Failure?

1. Enhancing Reliability

The Physics of Failure plays a crucial role in asset management and reliability by providing a deep understanding of why assets may fail. This knowledge allows organizations to anticipate and mitigate potential issues before they escalate, thus increasing the overall reliability of assets.

2. Predictive Maintenance

Understanding the physical processes that lead to failure enables predictive maintenance strategies. By identifying early signs of deterioration or stress, organizations can schedule maintenance activities more efficiently, reducing downtime and extending the lifespan of assets.

3. Cost Reduction

Implementing Physics of Failure principles in asset management helps in cost reduction. By addressing the root causes of failures, organizations can avoid costly emergency repairs and extend the life of assets, leading to more efficient resource utilization.

4. Optimal Design and Materials

Incorporating Physics of Failure principles in the design phase allows for the selection of materials and construction methods that minimize potential failure modes. This proactive approach ensures that assets are built to withstand the expected stresses and environmental conditions.

5. Safety Improvement

Understanding failure mechanisms contributes to safety improvement. By addressing potential failure points, organizations can enhance the safety of their assets, preventing accidents and ensuring a secure working environment for personnel.

6. Regulatory Compliance

Applying the Physics of Failure in asset management helps organizations comply with regulatory standards. Proactively addressing potential failure points ensures that assets meet industry regulations, reducing the risk of penalties and legal issues.

7. Long-Term Performance

By incorporating Physics of Failure principles into asset management strategies, organizations can enhance the long-term performance of their assets. This proactive approach ensures that assets operate efficiently and reliably over an extended period, contributing to sustained success.

How Is The Future of Physics of Failure?

The Physics of Failure (POF) is a crucial tool in understanding why electronic, electromechanical, or electrical components fail. It has significantly transformed the fields of electronics and engineering. As technology advances, there is a growing demand for better-designed and more complex equipment, especially in industries like oil and gas, petroleum, petrochemicals, and energy.

Consumers today expect devices to be faster, more efficient, and more reliable than ever before, as seen in the constant competition between companies like Apple and Samsung to release improved smartphone models each year. This trend extends across various industries, including defense, consumer products, automotive, and healthcare.

The ongoing evolution of electronics is a direct response to the increasing demand for Internet of Things (IoT) devices, electrification, and autonomous transportation in sectors like oil and gas. However, with these advancements come new possibilities for failure. This is where the continued application of POF proves to be invaluable in ensuring the reliability and longevity of critical systems within these industries.

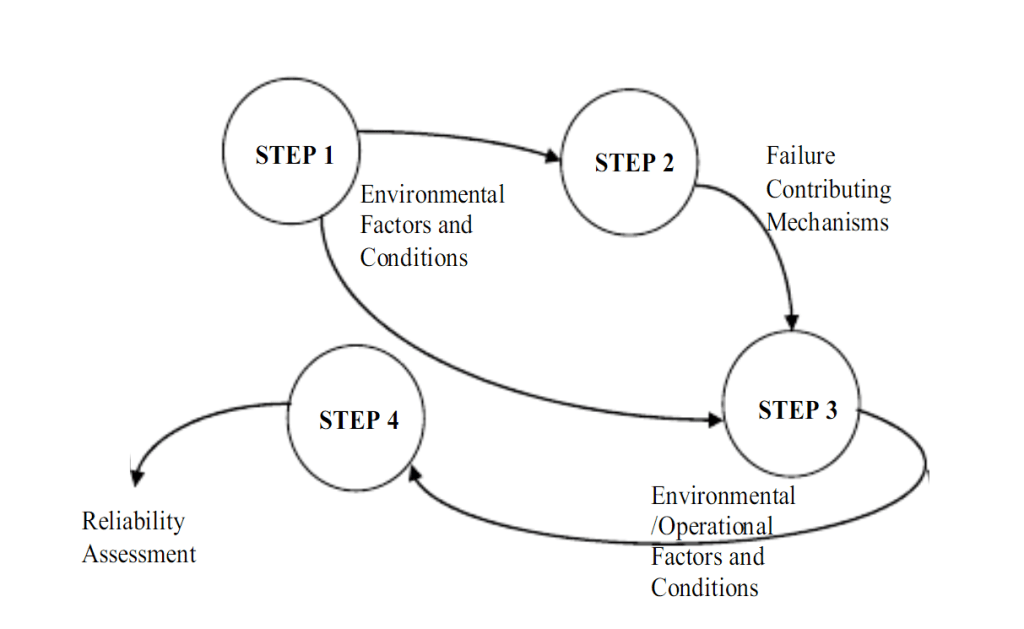

How Is The Procedure of Physics of Failure?

According to Vlado Sruk, Literature Review and Standardization Efforts, the examination of existing literature on the Physics of Failure (P-o-F) highlighted discrepancies in the procedural steps, revealing a need for a standardized approach. This paper aims to define a generic P-o-F procedure, providing a uniform set of steps applicable to any P-o-F analysis.

1. Determine Environmental Factors

Identify and measure relevant environmental conditions, setting the foundation for further analysis.

2. Isolate Potential Failures Triads

Sequentially determine failure triads (site, mode, mechanism), adapting the sequence based on available data. This step unifies the identification of failure sites, corresponding failure modes, and the mechanisms contributing to potential failure.

3. Filter Contributing Factors

After isolating failure triads and potential mechanisms, filter and prioritize contributing environmental and/or operational factors.

4. Identify Applicable Models

Determine proper functional dependencies for all stresses and identify models that best fit specified operational and environmental conditions. It is crucial to establish the validity bounds of each chosen model. Once the proper equations are known, calculate the life of components for any given operational or environmental condition within the model’s validity bounds.

By following these systematic steps, the P-o-F approach ensures a comprehensive analysis of potential failures, facilitating the development of reliable and effective strategies for mitigating risks in various operational and environmental settings.

In conclusion, mastering the skill of Physics of Failure (P-o-F) is crucial for effective asset management and reliability strategy. Understanding the reasons behind potential failures allows organizations to proactively strengthen the reliability of their assets. This skill is essential for minimizing downtime, optimizing overall performance, and adapting to technological advancements.

As industries increasingly rely on advanced equipment, applying P-o-F principles becomes a strategic advantage, ensuring dependable and efficient operation. Embracing this skill empowers organizations to make informed decisions, reduce risks, and establish a strong foundation for long-term operational success in our rapidly advancing technological landscape.

As you consider the critical importance of mastering the Physics of Failure (P-o-F) in ensuring reliable asset management, it becomes evident that furthering your knowledge in maintenance planning and scheduling is an invaluable step. PetroSync offers training programs that not only cover the essentials of maintenance planning but also delve into the intricacies of P-o-F.

Our Maintenance Planning and Scheduling training provides a comprehensive understanding of how to proactively address potential failures, minimize downtime, and optimize asset performance. By enrolling in Petrosync’s training, you gain a strategic advantage in navigating the challenges of maintenance and reliability, making informed decisions, and contributing to the long-term success of your organization in a rapidly advancing technological landscape.

Credit header image: Vecteezy

SEO specialist by day, fact-checker by night. An avid reader and content writer dedicated to delivering accurate and engaging articles through research and credible sources.